| Home

Club Info Ideas & Builds Downloads Newbie Calendar Interclub Series |

Omerta

New "Pylon" Fuselage available 15 March 2014 Further improvements have been made to the fuselage: plastiline is now used during the cure to avoid wrinkling of the cloth in the pylon, nose and rear area. Precise jigs are also now used to precisely locate the wing nuts while the two fuselage halves are still in the moulds. The operation is much tidier and faster than before. The two halves are then joined together using, once again, the mould to guarantee perfect alignment.

The fuselage in the pictures is for an ALES airframe. Canopy is much more user friendly than a nose cone for such an application. Therefore the fuselage is reworked: the hatch is obtained by carefully cutting the existing pod. Another component, with the shape of the landing for the hatch, is laid into the mould and cured. It is then routed to the shape of an "O", sanded and prepared to be glued in piece. The component is kept in place using clothespins. The hatch is eventually refined to match the pod.

This process is quite lengthy. It is mostly due to the fact we are using a mould which was designed for the Kuda, which has no canopy at all but a nose cone sliding forward to grant access to the radio gear. The mould seam is therefore vertical to allow the draft necessary to extract a fuselage pod with a pylon. A new mould is on its way to solve the issue and simplify the build of ALES airframes. New Omerta mk2 Outer Wings 1 March 2014 Jacques has delivered the second outer panel of the wing of Stephane: the finish is superb. Stiffness and weight, less than 10 ounces each, at rendezvous. Kudos to Jacques! His production rate is impressive and the final product is up to snuff in all departments. Bravo!

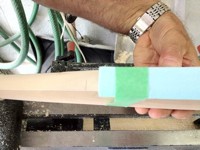

Bolt Beam Installation 4 February 2014 The bolt beam is the structural element holding the bolts that join the wing to the fuselage. It is a beam made out of balsa with carbon caps and wrapped with glass. The carbon caps are a by-product of the wing spar: in fact we use the remaining bit of the pre-cured caps trimmed to length for the central panel. Altogether the bolt beam weights 18gr. The central portion of the foam is removed and the spar web is carved away in the middle to allow the bolt beam being glued touching the spar caps. Then different ribs are placed. The remaining volume is filled with foam and sanded to airfoil before bagging the wing skins.

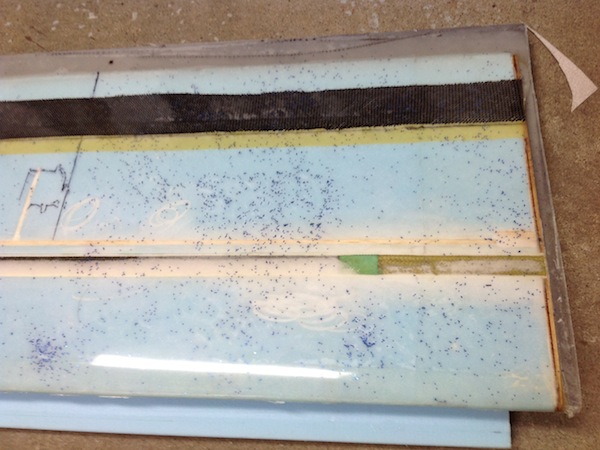

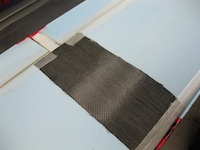

Omerta mk2 - First Wing panel ready! 9 January 2014 The new wing for the 2014 ALES season is lighter, stronger and with a better finish than the previous prototypes, still keeping the manufacturing costs down to a minimum. In fact we used glass cloth for the skins: 2 plies of 1.5oz/yd plus local reinforcements at the panel root. The servo bay is reinforced with carbon cloth. Paint is laid on molars in order to give the homogeneous and shiny finish you can see . The weight stacks up to 336 grams only, ready for servo installation. A great achievement!

Built-up Stabiliser and Rudder 31 March 2013 The latest creation of the MATS men'cave is here! The unit has been weighted at 22 grams and tested on a 3 points bending setup applying 10 lb at the root (supports were at 8in span). This glider is going to be centred without using any ballast…mission accomplished!

The rudder has been fabricated using the same technique. Ribs and spars have been CNC cut and then assembled together. The spar has not been wrapped with kevlar since the reduced load combined with the way thicker airfoil, used to accomodate the servo without protruding in the aerodynamic flow, can withstand the load as is. Here you can have a look to some pics taken during the build sequence. Enjoy!!!

Built-up stabiliser 26 February 2013

Who better than one of the actual builders can describe what went into this new trial? Here's Marco talking about the new prototype: "We did some calculations trying to see if we used too much CA. Final answer was the we probably did, but not that too much. After talking about it over our last glass of wine, we were about to conclude that builtup is not much worth the effort. But once again, a sign came. We looked at my fast-assembled, crooked prototype i made this morning and found what went wrong... BALSA! The balsa on my stab was premium quality, ultra light, but the balsa we used for the d-box was too heavy. It ruined all our previous efforts. So we've learned a real lesson tonight. This project is not over! Other than that, we improved the construction technique that i used this morning. We used 0.2mm carbon cap for the spar instead of 0.5mm. We also wrapped the spar with kevlar tow. A nice move that only added 1g. Next time we should try to use thinner tow." And here some detail pictures of the result!

First Omerta ready for radio gear installation! 16 Jannuary 2013 Jacques sent me the pictures of Marco holding the first Omerta coming out of our assembly line. Marco is going to install all the radio gear needed to put his ship in the air. . .as soon as the snow will leave our flying field! Until then new machines are being prepared in Jacques' shop. Stay tuned!!!

New fuselage mould 19 November 2012 Stephen has just finished the new mould for the fuselage. As designed, the new mould allows more space for battery underneath the wing saddle. 4S LiPo batteries will slide in giving pilots the easiest way of locating the centre of gravity without using extra ballast. The mould is manufactured using epoxy and glass fiber. Stephen had a sheet of honeycomb which made up for a light yet sturd and stiff mould. I am sure it will serve the MATS members for a lot of time without any distortion!

Omerta ready to fly!!! 18 September 2012 Omerta is ready to fly! Have a look to the latest pictures of the model assembled before maiden!

Interim fuselage assembly 12 September 2012 A Kuda TD fuselage has been used as a bench airframe for the Omerta wing, which is now ready to fly. The Kuda is a pylon mounted wing glider and the access to the radio gear is granted through a sliding nose cone. The first operation then is to make this fuselage compatible with a motor installation. The nose cone has been cut in order to create a canopy. The underlying structure has been cut slightly smaller so that it provides the landing for the canopy once the two are bonded together.

The firewall has been cut and drilled to allow installing the MVVS 46 5.6/960 Redline motor. The firewall has been installed with an angle of 4 degrees rightwards and 5 degrees downwards to counterbalance the gyroscopic effect of the prop while turning.

Wing finished 28 August 2012 The full wing is finished and ready to be installed. Lacking the new fuselage the wing has been installed on a Kuda fuselage, just to see how it looks like. Bolt holes have been drilled into the bolt beam keeping 4 in distance so that the wing is compatible with the TD fuselages.

Tip Panels cured 25 August 2012 Tips have been cured and look very good. They have been preliminarily deburred and weighted.

Tip panel foams ready to go 23 August 2012 Tip foams are being prepared: foam blocks have been cut to airfoil, joined together, and sanded in order to accommodate spar caps and joiner boxes. The weight prior to bagging is 153 gr each, as expected!

Central Panel cured 21 August 2012 Two Central Panels have come out of the owen. The skins have bonded perfectly and the ratio weight/stiffness looks very good! Both panels weight 565gr prior to final trimming. Pretty much on target!

If you are asking yourself what are those tiny bits shining through the fiberglass…well, those are our "bits of fanciness"…unfortunately, while nice to see, those have proven quite difficult to install and not as shiny as foreseen once in flight. Indeed, they are a good topic of discussion while our friends are at field between a flight and another!

The tip panels spars have also been bonded in place. Good old bricks and a couple of aluminium square extrusions help keeping everything in place perfectly straight while epoxy is setting.

Upper skin local reinforcements in place! 31 July 2012 Once servo harness, aileron facings, main spar and leading edge glass strips in place, the upper skin reinforcements have been placed with the help of good old 3M77 spray glue. A centre patch of 1.5oz carbon has been chosen for the wing root covering the beam bolt while 2oz fibber glass has been used for the tips of the central panel.

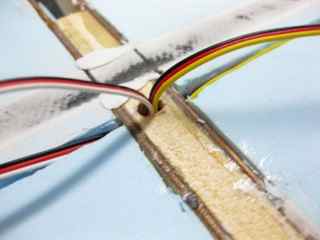

Wing and Harness - A different flavour! 30 July 2012 Marco has started off his wing: he's working at a fast pace to catch-up with Jacques. He has chosen a slightly different approach to the build: his harness is going to be extra light. In fact he has replaced standard silicon covered copper cables with enamel covered copper wires. This technique was in vogue some years ago for hollow moulded F5B wings (as far as I recall Weissgerber won a WC with a wing cabled like so) and has proven very good results. Kudos to Marco to bring it up and apply it in such a flawless way!

Wing Harness 27 July 2012 Harness is installed prior to final bagging of the lower side of the central panel. Foam is removed using a square edge and a soldering iron, then after the installation of the cables, speckling is used to restore aerodynamic profile of the wing. The plug receptacle is filled with a piece of foam, and little spackling is used for the final touch.

When the work is finished the joiner box is sealed with a block of foam to avoid any issues with vacuum during curing and preventing any resin flowing into the box during the cycle.

Wing Root 16 July 2012 The bolt beam has been installed at the wing root location. The beam has been carved to allow cables connecting to the fuselage harness. Laser cut ribs are installed to give reference and facing for the ailerons bonded with 3M77. The empty volume left between the wing facing and aileron facing is going to be filled with foam in order to allow proper bagging during cure of the lower skin.

Wing Joiners 10 July 2012 Square joiners are being produced using pre-cured strips of carbon 0.007" thick bonded together.

A mould gives the right dihedral angle and guarantees repeatability and interchangeability of each joiner.

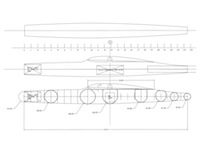

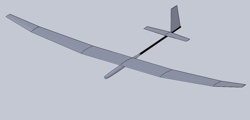

A 4m wingspan ALES glider! June 2012 A new model dedicated to ALES is being built by MATS members. It is derived from our experience with the TD SupraKuda and ALES eBD previous designs. The model will be declined into different versions to suit different pilots tastes, and will involve more CAD definition to be able to use 3D printing techniques. The wingspan has been set to 4m for maximum performance. Flaps and ailerons will be installed in all cases. Movables will be actuated using RDS mechanism and a new building technique for the wing is being tested.

Fuselage A brand new fuselage has been designed, in order to carry 4S battery packs easily, which was one of the limitations of the eBD fuse. Jacques defined the new layout based on the new set of objectives:

The fuse is built starting by spinning and carefully sanding a piece of basswood on a lathe, based on Jacques, Marco, Steve and Duc brainstorming during a very proficient "coffee & CAD" evening.

After long hours of spinning the mandrel (as one can see in the picture our fellows showed some signs of tireness that night!!!) and after having tried out themselves to verify they didn't build a baseball bat instead of a fuselage...

...they came up with a beautifull mandrel ready for the next step or our mold fabrication!!!

Wing to fuse fairing will be integrated in the mould after the completion of the mandrel which has been spun accurately on a lathe. The work is well underway with the wooden part of the job being completed and the fairing coming soon.

Wing Airfoils are the same of the SupraKuda but the wing planform and dihedral are different making available two different versions: the first one will feature multiple dihedral (inspired to the eBD) with ailerons installed only on the mid panel, while the second one, whilst keeping the central panel flat, will feature only one dihedral and ailerons spanning to the very tip of the wing.

The first wing has been started using a new structural configuration. Jacques has carved the volume corresponding to the spars out of the cores with the CNC hot wire machine. The spar is pre-cured and then inserted into the slot already present in the wing achieving very precise positioning, reducing spackling to the very minimum and minimising manufacturing time. Since minimum rework is needed the airfoil is reproduced with high precision.

RDS is being tested by Steve: the wiper rod (0.125" music wire, a little overkill) is soldered to 0.156"O.D. brass tube torque shaft, 2" long. The torque yoke is 2 pins of 0.61"dia, CF rod lashed to the end of the torque shaft with 3k CF tow soaked with CA. A little jig has been made to ensure proper spacing. The result weights 4g and seems as solid as can be. The CF tow starts out as a hairy mess and ends up looking like black steel. |

| Last update 17 September 2014

|

||

| Contact the

webmaster |